Clay Settlement

Alternative sustainable construction material in Singapore context

-

Singapore is constantly searching for new alternative

construction materials to reduce the reliance of importing from neighboring countries. It is projected that the upcoming big-scale subterranean projects in Singapore will produce a large amount of excavated clay soil that has the potential to become a new construction material.

Conventionally, clay is used to produce clay bricks and architectural ceramics, which are commonly used as facade treatment. The thesis seeks for innovative uses of the excavated clay to create a new clay product that works beyond the conventional clay products.

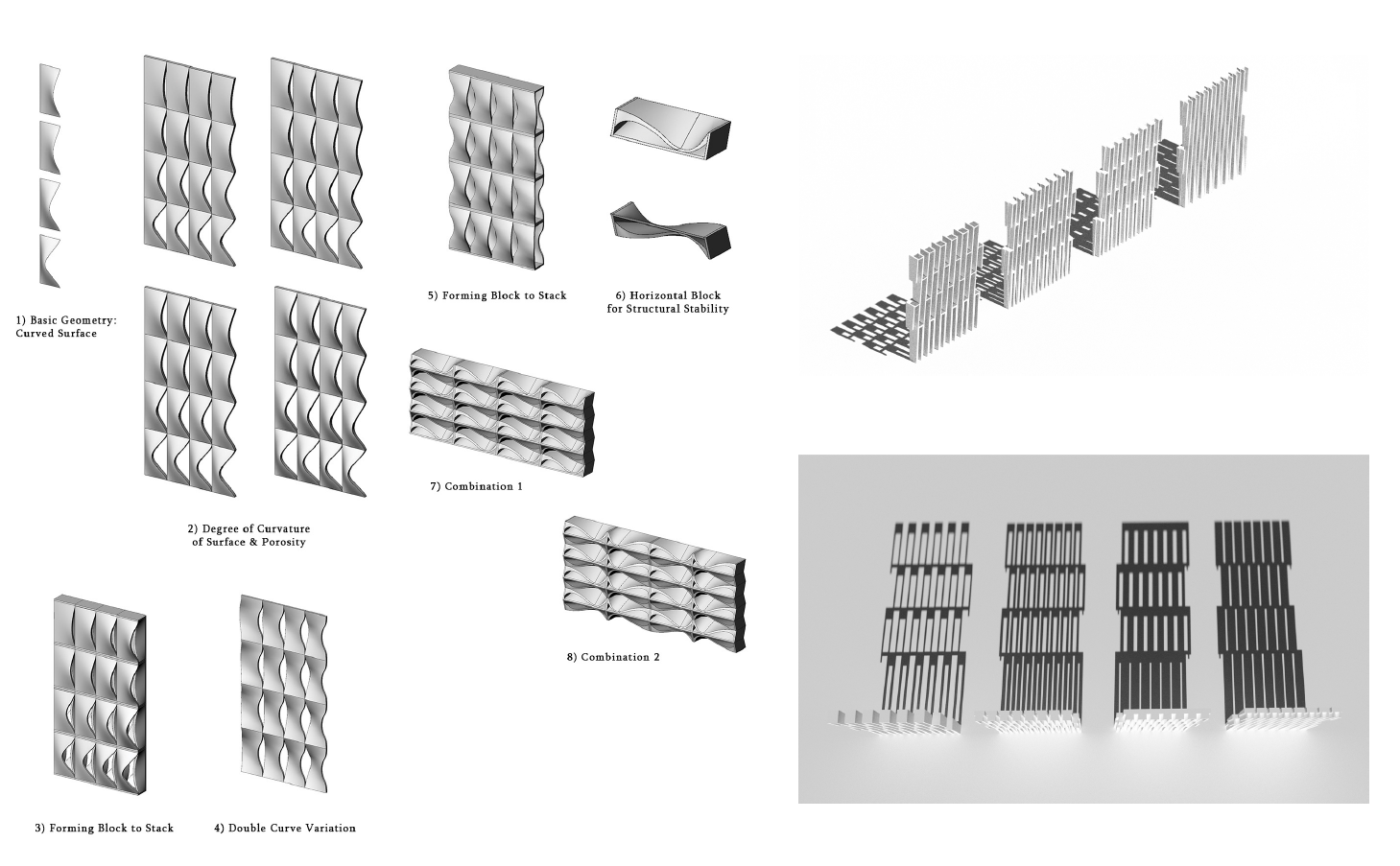

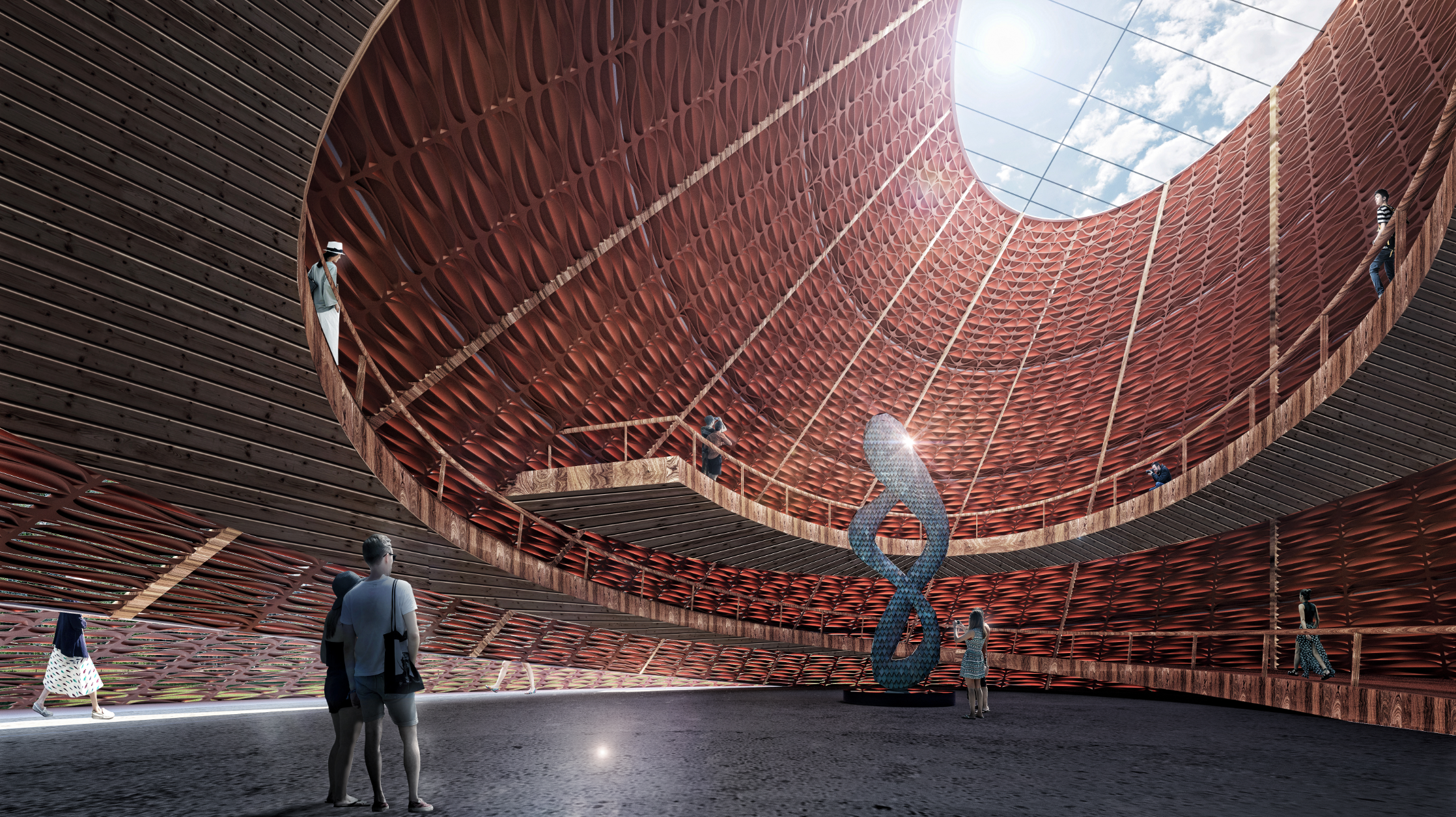

The new clay products can address Singapore's tropical climate and structurally self-support. The fundamental understanding of the material is acquired through a series of theoretical research and actual experiments with clay. The technique of casting is adapted to conduct the clay experiments. From the experiments, the achievable geometry and the extent of complexity in using clay are investigated. The experiment results will then form the parameters for the process of designing with clay and drive the tectonic of architecture.

The design process began with designing the basic unit of architecture – a "cell", which can be duplicated to form structures. The cells have been tested with digital structural simulation to make sure the design is able to self-support.

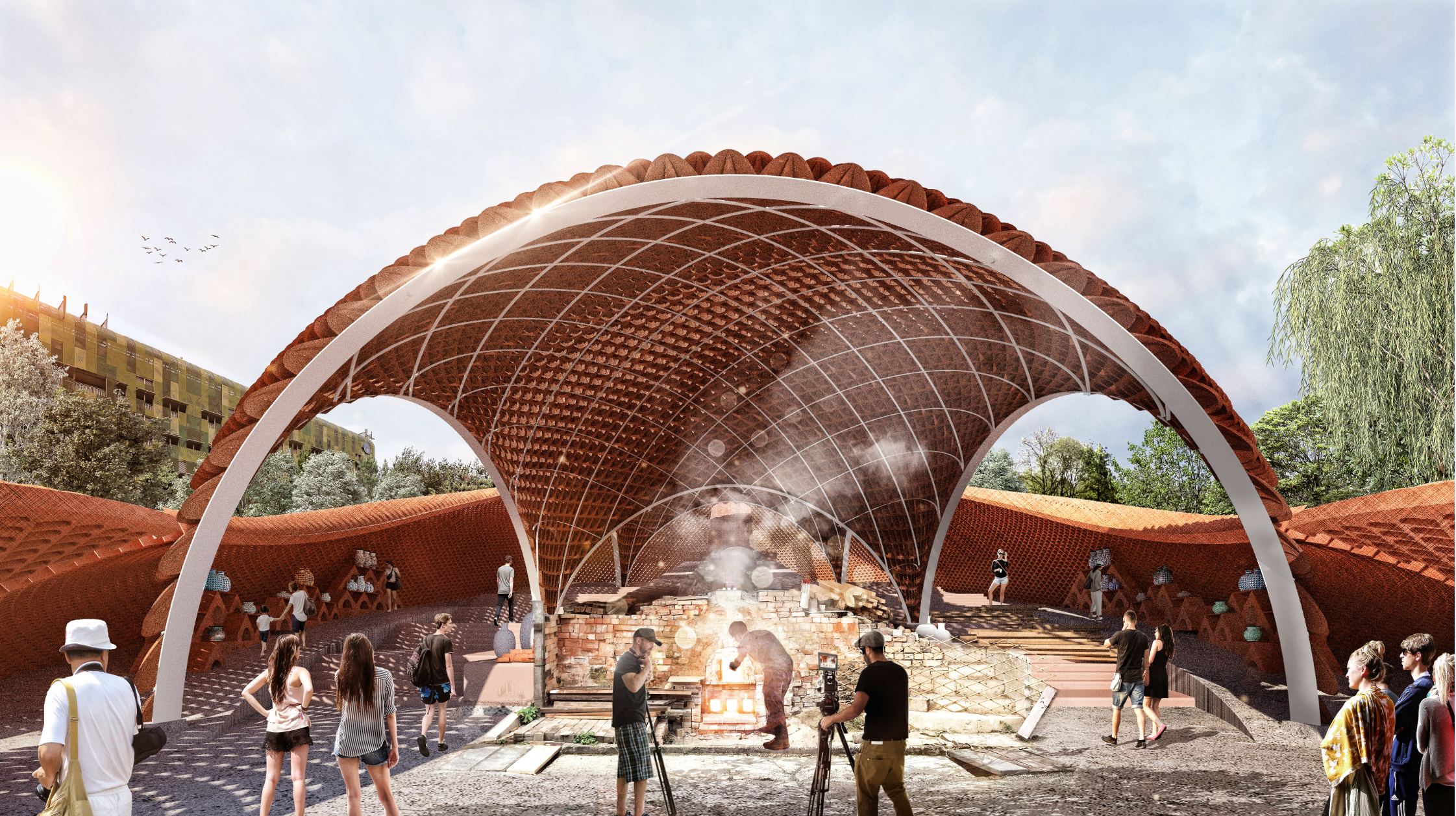

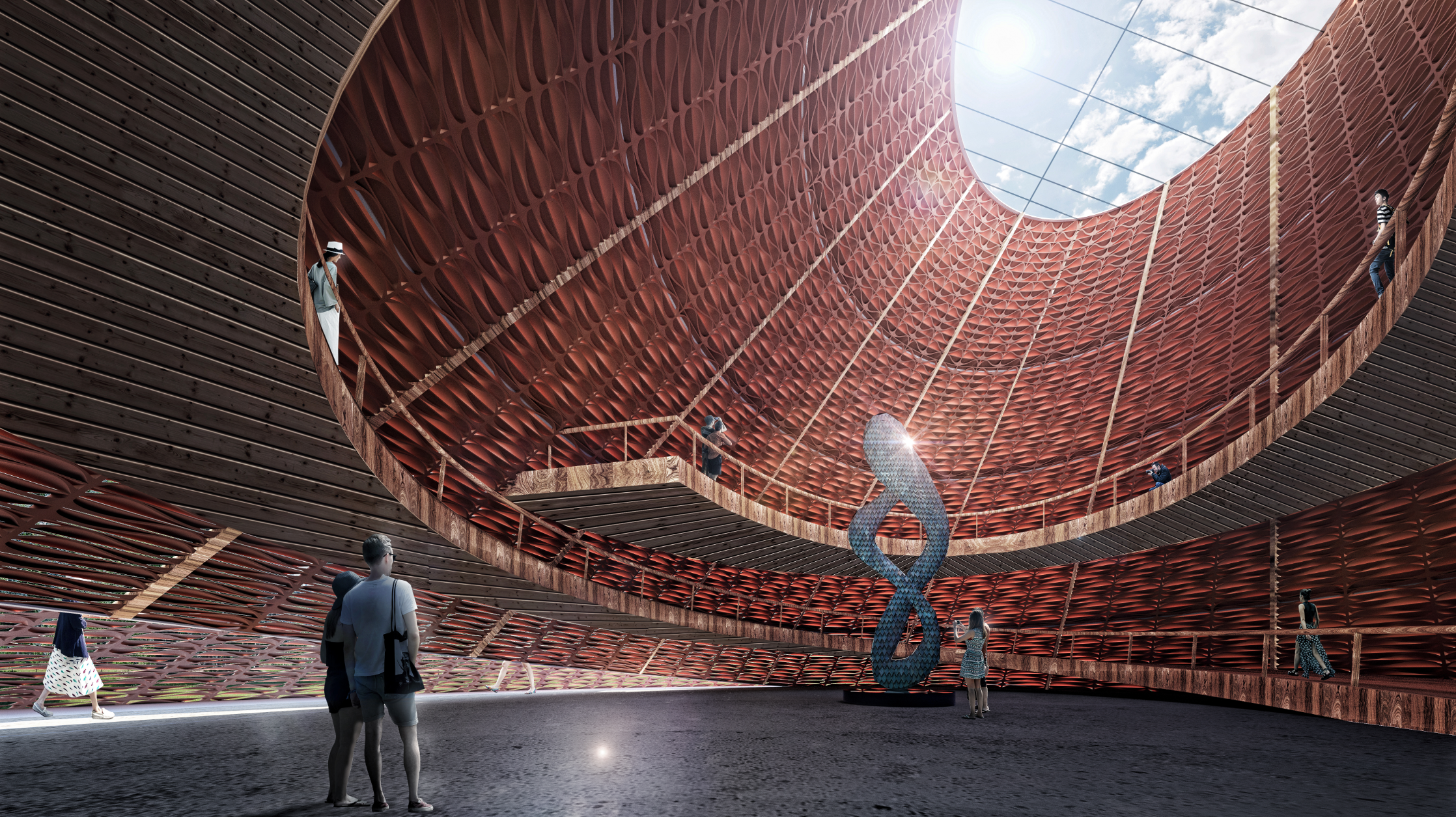

The clay cells will be used to create enclosures and pavilions in the masterplan - Clay Settlement. It is situated within the new Clean Tech Park, where the last two surviving Dragon Kilns in Singapore reside. Clay Settlement is a place for the public to learn and experience pottery art in a garden setting. With the introduction of new programs, it preserves the historical Dragon Kilns and pottery activity which has taken place at the site since 1920s.

-

TYPOLOGY: Pavilion

PROGRAM: Cultural facilities

LOCATION: Clean Tech Park, Singapore

YEAR: 2019

STATUS: Concept

-

Winner- Pertubuhan Arkitek Malaysia (PAM) Student Awards 2020

Clay as alternative construction material

The construction industry in Singapore relies heavily on concrete and steel, as 90% of building construction in Singapore is concrete-based. With no mining sources and manufacturing plants, Singapore has been relying on importing construction materials, especially cement, steel and sand from neighbouring countries. The sand crisis in 2007 caused a spike of 75% in concrete prices, signalling there is a need to reduce reliance on concrete and move towards more sustainable construction methods.

As the Ministry of Development stated in a media release in January 2007, “…Shift towards less concrete-based construction will help advance Singapore’s construction industry towards a ‘sustainable construction’, one that adopts the greater use of more renewable materials and more environmentally friendly methods of construction, there is a need to seek for a new alternative to reduce the reliance on importing.

Due to extensive underground development, Singapore produces an abundant amount of excavated

soil. An estimated 924, 200 m3 of soil was excavated from the construction of Circle Line Mass Rapid Transit in 2011. In the same year, 8.5 million m3 of soil was excavated to build basement car parks, shops, underground expressways, and MRT tunnels. However, the excavated soil is not utilized efficiently as statistic shown in 2011, only 50% (3.9million m3) of excavated soil were used for a reclamation project in Pulau Tekong, whereas the other half was disposed at an offshore dumping site at St John Island. In the Underground Masterplan 2019 which will be revealed by the Urban Redevelopment Authority, it is expected that there will be more underground developments in the upcoming years and the amount of excavated soil will also increase.

In addressing the surplus of excavated soil, the former National Development Minister Mr. Khaw Boon Wan has also called for innovative ways to turn excavated materials into useful construction material.

OBJECTIVE

Conventionally, clay is used to produce clay bricks and architectural ceramics, which are commonly used as facade treatment. The thesis seeks innovative uses of the excavated clay to create a new clay product that works beyond the existing clay products. The new clay products aimed to address Singapore's tropical climate by being able to:

i. control sunlight

ii. allow natural air ventilation

iii. prevent rainwater penetration

It also has to be structurally self-supporting to work as a basic building material.

The clay product will create enclosures and pavilions in the masterplan - Clay Settlement - a strategy to rejuvenate the current Dragon Kiln site and preserve the historical artefact from demolition. It will be a hub for people to learn and create pottery art in a garden setting at the same time integrated with the surrounding as a green sanctuary within the eco business park.

Clay Cell Typology Studies

Type 1: Dragon Scale

Type 2: Rain Spout

Type 3: Vent Block

Dragon Kilns and Pottery Industry in Jurong

Lorong Tawas, Jurong is where the last two remaining Dragon Kiln in Singapore reside. In early 20th century, Jurong is well known for its pottery and bricks industry. It is a fertile ground of clay and provides abundant amount of good quality clay for local production. Dragon Kiln, a traditional wood firing kiln, was then used by the factories to fire the clay products.

Uncertain Fate of The Dragon Kilns

The manufacturing based industry started to lose its significance as Singapore was transitioning to knowledge based economy after independence. In 1990s, many dragon kilns were demolished to make way for urban redevelopment, left the last two remaining dragon kilns – Thow Kwang Dragon Kiln, own by Thow Kwang Pottery Jungle and Guan Huat Kiln at Jalan Bahar Clay Studio. The Dragon Kilns are facing the uncertainy of being demolished to make way for the new Clean Tech Park, the first eco business park in Singapore which will be completed in 2030. Both Dragon Kilns are given a temporary occupation license that needs to be renewed every 3 years. Its current lease is valid till 2024. Despite that, the local potter groups are expecting a pessimistic result.

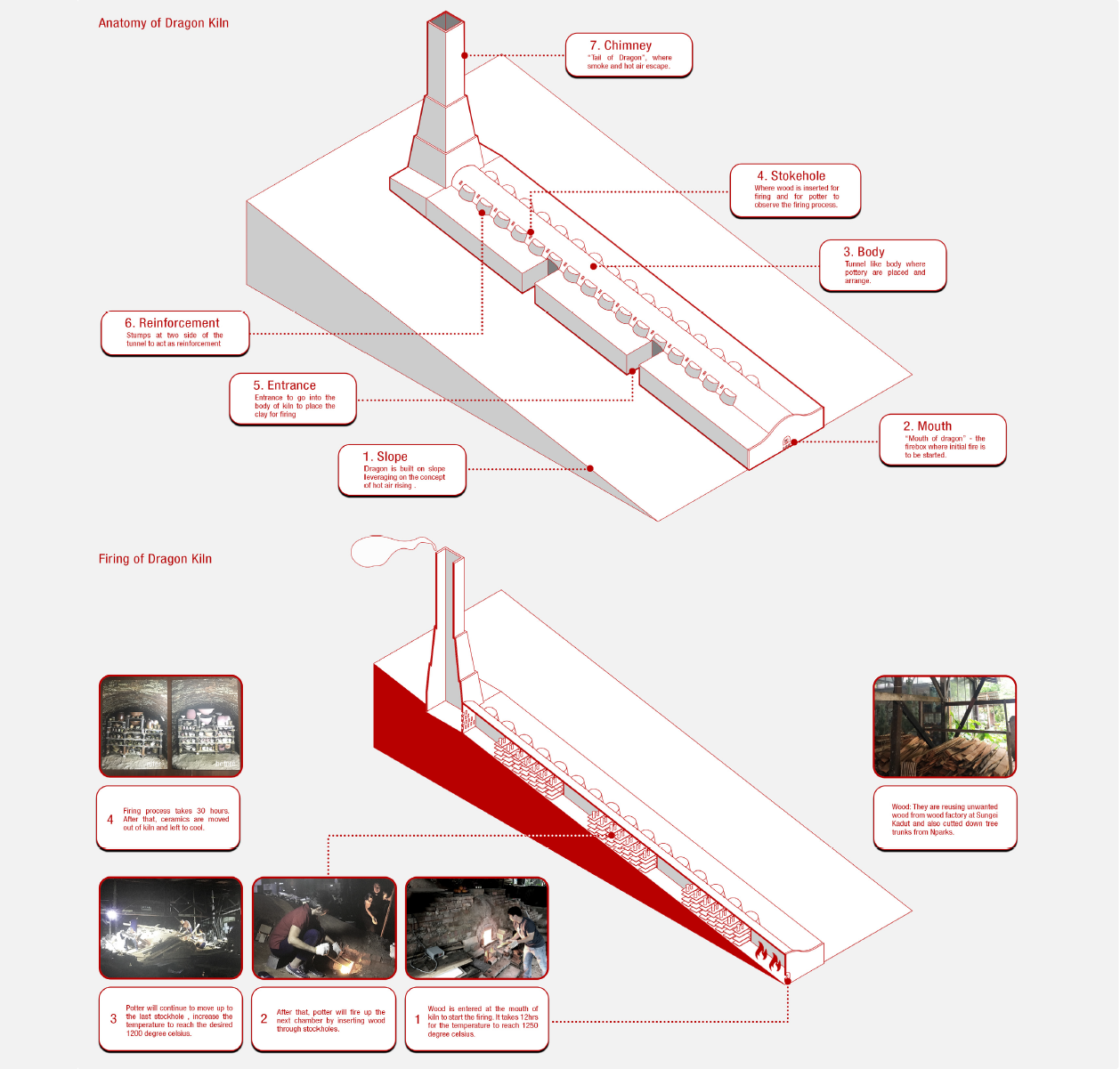

The Dragon Kiln

Originating from Teochew, China, Dragon Kiln was introduced by Chinese ancestors to Singapore in the 1920s. Constructed of brick arches, the kiln was built climbing a 15-20 degree slope. The firebox was at the bottom and the flue at the top to encourage the flow of heat through the furnace. Unfired porcelain items were placed in a kiln furniture box made of refractory clay such that ware could be stacked and placed along the whole length of the kiln.

Site Selection

As part of Jurong Innovation District, Clean Tech Park is the first eco business park in Singapore, owned by JTC Corporation. It is an R&D and test-bedding site for early adoption of technology and solutions with prototyping labs, start up facilities, co-working spaces and residences.

The masterplan is evolving around Jurong Eco Garden– the central green core that act as the green lung of the business park. The garden aims to protect the existing ecology and bring tropical rainforest closer to businesses.

Despite the ongoing construction of CTP, JTC Clean Tech One, JTC Clean Tech Two JTC LaunchPad and Jurong Eco Garden are currently completed and open for access.